Sedgman is a proven provider of mineral processing and associated infrastructure solutions to the global resources industry, specialising in the design, construction and operation of mineral processing and crushing plants across a growing number of commodities including coal, metals, and iron ore.

Our operations are cost-effectively achieving industry best operating hours annually and we have a record of exceeding budgeted throughput rates, metallurgical recoveries, and product volumes. When operating plants that we have designed and built, our integrated capability drives even greater optimisation. When operating plants designed by others, we draw on our in-house engineering bench strength, and knowledge database across multiple sites, to achieve maximum performance.

Sedgman Operations and Optimisation

With over 20 years of experience in delivering processing, materials handling and tailings management services, Sedgman Operations achieves industry-leading performance in metrics such as safety performance, run hours (availability and utilisation), recovery and grades, metallurgical efficiency, and unit operating costs. This is driven by effective optimisation strategies, reliability engineering, and preventative and condition-based maintenance practices. Streamlined processes, lean teams and our 360º feedback loop into design and project delivery also enable us to deliver operational improvements. For our clients our approach results in high-level responsiveness, sustainable efficiency, performance reliability, and reduced unit costs.

Sedgman has a proven track record of helping clients in modification of their existing assets for efficiency optimisation, debottlenecking, implementing new technologies, refurbishment, and sustaining capital works. The experience and expertise we have gained through execution of a spectrum of mineral processing projects help us evaluate design specifications and margins and determine the best way to accommodate new and desired operating conditions.

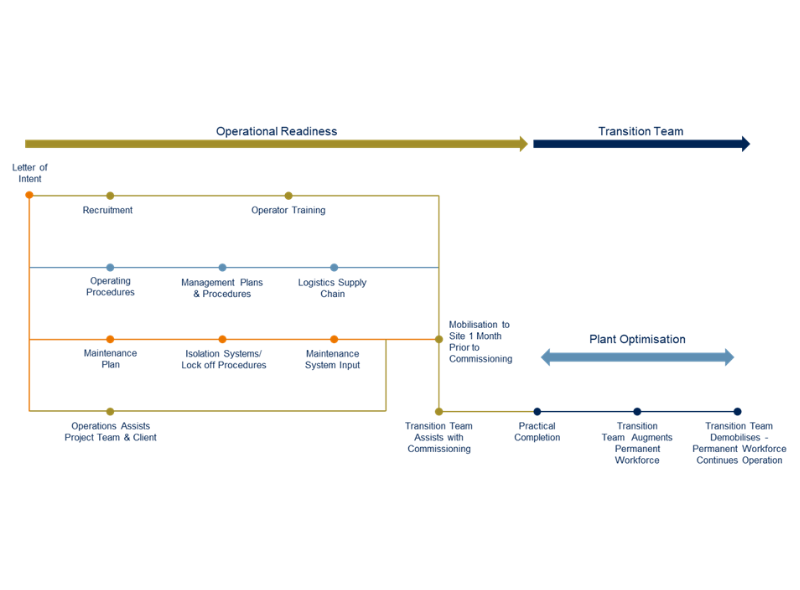

Our flexible services include mineral processing facility operations, maintenance, auditing, debottlenecking and upgrades, alongside operational readiness and transition support.

Sedgman has been performing contract operations since 1997 and focuses on three key areas to deliver exceptional mineral processing operations results:

- Focus on innovation and optimisation of operational performance

- Effective operational and maintenance systems which are under-pinned by technology

- Effective remote monitoring providing expert support to complement our site-based teams' capabilities